In 2025, choosing the right jewelry laser soldering machine can greatly impact your repair work. With options like the Jewelry Laser Welder 150W and the Automatic Spot Welder, you’ll find tools that cater to precision and versatility. Each machine offers unique features that enhance the welding process, making them essential for any professional jeweler. But how do you decide which one fits your specific needs? Let’s explore the top contenders and what sets them apart.

Jewelry Laser Welder 150W for Jewelry Repairs

If you’re a jeweler looking to enhance your repair capabilities, the Jewelry Laser Welder 150W is an excellent choice for you. With its 150W power and versatile applications, you can effectively weld gold, silver, platinum, and more. The 1064nm laser wavelength allows for precise welding depths between 0.1-2.5mm, making it ideal for intricate jewelry repairs. The user-friendly digital control system and automatic shading guarantee safety and ease of use. Plus, with a 1-year warranty and lifetime technical support, you can feel confident in your investment. This welder’s features make it a top contender for quality and precision in your workshop.

Best For: Jewelers seeking a reliable and precise solution for intricate jewelry repairs across various metals.

Pros:

- Versatile Applications: Capable of welding multiple materials including gold, silver, platinum, and more.

- User-Friendly Interface: Features a digital control system with a capacitive touch screen for easy operation.

- Safety Features: Equipped with an automatic shading system to protect eyes from laser exposure.

Cons:

- Initial Cost: The upfront investment may be high for small-scale jewelers.

- Cooling System Limitation: Air cooling may not be sufficient for extended heavy use.

- Limited Welding Depth: Maximum welding depth of 2.5mm may not meet all repair needs for thicker materials.

Automatic Spot Welder Pulse Argon Arc Welding Machine for Jewelry

The Automatic Spot Welder Pulse Argon Arc Welding Machine is an excellent choice for jewelry makers seeking a reliable and efficient welding solution. With a welding range of 50-600A and 100W power, it effectively welds various materials, including gold and titanium. Its compact design makes it easy to handle, while the heavy-duty stainless steel construction guarantees durability. Operating this machine is straightforward, enhancing safety and stability during use. Ideal for DIY projects and repairs, it includes essential components like a CNC spot welder and tungsten needle. Despite mixed reviews, many users appreciate its build quality and welding capabilities.

Best For: Jewelry makers and DIY enthusiasts looking for a compact and efficient welding solution for various materials.

Pros:

- Pulsed Argon Arc Technology: Offers a cost-effective alternative to laser welding with effective results.

- Durable Construction: Made from heavy-duty stainless steel, ensuring longevity and reliability.

- Easy to Use: Designed for straightforward operation, enhancing safety and convenience during welding tasks.

Cons:

- Mixed Reviews: Customer feedback indicates concerns regarding the quality of components and instructions.

- Limited Effectiveness on Some Materials: Some users report difficulties when welding certain materials.

- Low Customer Rating: With a rating of 2.6 out of 5 stars, the product has received several complaints affecting its overall perception.

Jewelry Automatic Spot Welding Machine for DIY Jewelry Repair

For DIY enthusiasts looking to repair jewelry at home, the Jewelry Automatic Spot Welding Machine stands out with its efficient pulsed argon arc technology. Weighing just 8KG, its compact design makes it easy to handle. You’ll love the one-key switch welding mode with five quick adjustments, allowing you to tailor power and welding time. This versatile machine works on pure gold, silver, titanium, and more, perfect for various projects. Plus, it operates effectively with or without argon gas, although using it enhances welding quality. It’s a cost-effective solution, giving you professional results without breaking the bank.

Best For: DIY enthusiasts and hobbyists looking for an efficient and cost-effective solution for jewelry repair at home.

Pros:

- High efficiency with pulsed argon arc technology provides professional-quality results.

- Compact and lightweight design (8KG) makes it easy to handle and store.

- Versatile welding capabilities for various materials including gold, silver, and titanium.

Cons:

- Requires careful handling to avoid short-circuiting the electrodes.

- Optimal performance is achieved with argon gas, which may incur additional costs.

- May have a learning curve for beginners unfamiliar with welding techniques.

Jewelry Wax Welder for Jewelry Making

Crafted specifically for jewelry makers, the Jewelry Wax Welder by Wene stands out with its instant heating capability and adjustable temperature settings, making it ideal for both professionals and hobbyists. This compact soldering tool is constructed from high-quality metal and plastic, ensuring durability and longevity. You’ll appreciate its ease of use, allowing for precise welding with one-handed operation. The welder’s portable design means you can easily use it at home or on the go. Plus, with professional customer support available, you can rely on assistance whenever you need it. Elevate your jewelry-making experience with this efficient tool!

Best For: Jewelry makers and hobbyists seeking a reliable, portable, and precise soldering tool for their crafting needs.

Pros:

- Instant heating feature allows for quick operation, saving time during projects.

- Adjustable melting temperature (0℃ – 370℃) accommodates various materials and welding requirements.

- Compact and portable design makes it easy to use in different locations, whether at home or on the go.

Cons:

- May require careful handling to avoid overheating and burnout if not monitored properly.

- Limited to welding specific materials like cobalt chrome alloy, which may not suit all users’ needs.

- The weight (2.61 pounds) might be considered slightly heavy for prolonged use by some users.

WAINLUXPRO K10 Laser Engraver for Wood, Leather, Glass, and Cloth

Looking for a versatile tool that elevates your DIY jewelry projects? The WAINLUXPRO K10 Laser Engraver is your go-to solution. This 5000mW portable machine engraves wood, leather, glass, and cloth with precision up to 0.01mm. It cuts through 3mm pine boards effortlessly and supports offline engraving. You can control it via USB or WiFi from your phone, tablet, or computer. Plus, its safety features include an auto-stop function and tilt detection, ensuring worry-free use. With over 100 laser presets and a 12-month warranty, it’s perfect for personalizing gifts or creating educational projects. Get started today!

Best For: DIY enthusiasts and hobbyists looking to personalize projects with precision engraving on various materials.

Pros:

- High Precision: Engraves with 0.01mm accuracy, allowing for detailed designs.

- Versatile Material Compatibility: Can engrave and cut through wood, leather, glass, and cloth, as well as coated metals and plastics.

- User-Friendly: Easy to control via USB or WiFi from multiple devices, with no assembly required.

Cons:

- Limited Engraving Size: Maximum engraving area of 80x80mm may restrict larger projects.

- Additional Accessories Needed: Rotary attachment for round items and air purifier sold separately.

- Noise Level: While it operates quietly, some users may still find it louder than expected during operation.

YIHUA 926 III Digital Display Soldering Iron Station Kit

The YIHUA 926 III Digital Display Soldering Iron Station Kit is an excellent choice for jewelry makers and hobbyists who need precise temperature control for delicate soldering tasks. With a temperature range of 194℉ to 896℉ and fast heating capabilities, you’ll find it easy to adjust settings for different materials. The digital display guarantees clear temperature readouts, while the PID temperature stabilization keeps heat consistent. This kit includes essential tools like helping hands, extra iron tips, and lead-free solder. However, be mindful of the short power cord and occasional temperature stability issues. Overall, it’s a solid investment for your soldering needs.

Best For: The YIHUA 926 III Digital Display Soldering Iron Station Kit is best for jewelry makers and hobbyists requiring precise temperature control for delicate soldering tasks.

Pros:

- Fast heating capabilities with adjustable temperature settings for various materials.

- Digital display provides clear temperature readouts, enhancing user experience.

- Includes essential tools like helping hands, extra iron tips, and lead-free solder for convenience.

Cons:

- The power cord is relatively short, which may limit workspace options.

- Some users have reported inconsistent temperature stability during use.

- Issues with the solder sucker and lack of flux in the provided solder have been noted.

110V Adjustable Jewelry Spot Welding Machine

If you’re a jeweler seeking precision and efficiency, the 110V Adjustable Jewelry Spot Welding Machine stands out as an essential tool for your workshop. With a power output of 400W and adjustable settings, you can effortlessly weld materials ranging from 0.5 to 2.0 mm. Its compact design and comfortable handle make it portable, perfect for various projects. The high-frequency discharge plasma guarantees effective welding, while safety guidelines remind you to maintain proper grounding and wear goggles. Included in the package are essential accessories like tweezers and a foot pedal, making it a complete solution for your jewelry crafting needs.

Best For: Jewelers looking for a reliable and adjustable welding machine to enhance their crafting precision and efficiency.

Pros:

- Adjustable power output allows for versatility with various wire sizes (0.5-2.0 mm).

- Compact and portable design with a comfortable handle for easy transportation between projects.

- High-frequency discharge plasma enhances welding efficiency, ensuring strong and effective joins.

Cons:

- Customer feedback indicates a lack of clear instructions, which may lead to confusion for new users.

- Average rating of 3.4 stars suggests mixed experiences among users, highlighting potential reliability issues.

- Safety concerns have been raised regarding the operation, necessitating careful adherence to guidelines.

Automatic Spot Welder for Jewelry Repair Tool

For jewelers seeking a cost-effective solution for precise repairs, the Automatic Spot Welder Pulse Argon Arc Welding Machine stands out as an excellent choice. This welder combines the benefits of traditional welding with lower costs compared to laser options. Weighing just 16.42 pounds, its compact design allows for easy operation in various settings. It effectively welds pure gold, titanium, and cobalt chrome alloy, making it versatile for jewelry repairs and DIY projects. While it has received mixed reviews concerning instructions and quality, it still offers a solid warranty and a 30-day return policy for peace of mind.

Best For: Jewelers and DIY enthusiasts looking for an affordable and efficient solution for precise jewelry repairs.

Pros:

- Pulsed Argon Arc Technology: Offers advantages of traditional welding at a lower cost compared to laser welding machines.

- Durable Construction: Made from heavy-duty stainless steel, ensuring longevity and reliability.

- Compact Design: Lightweight and easy to operate, making it suitable for various work environments.

Cons:

- Lack of Instructions: Users report difficulties in operation due to insufficient guidance provided.

- Equipment Malfunctions: There are complaints regarding issues with the tungsten tip and overall equipment reliability.

- Mixed Customer Service Experiences: Feedback indicates inconsistent support and quality concerns from the manufacturer.

Twotrees TS1 Mini Laser Engraver

Looking for a compact and efficient engraving solution? The Twotrees TS1 Mini Laser Engraver delivers impressive performance in a portable package. With a powerful 3W laser and speeds up to 3000mm/min, it boasts a working area of 80x80x30 mm. Enjoy high precision thanks to its 0.1mm positioning accuracy and auto-focus feature. This engraver handles various materials, making it perfect for DIY crafts and small industrial projects. Control it via Bluetooth, USB, or TF card, and take advantage of its compatibility with popular design software. Despite mixed reviews, its compact design and functionality make it a solid choice for jewelry engraving.

Best For: Hobbyists and small business owners seeking a compact and versatile laser engraving solution for various materials.

Pros:

- High precision with 0.1mm positioning accuracy for detailed engravings.

- Portable design allows for easy transportation and use in different locations.

- Compatible with popular design software and supports multiple control options (Bluetooth, USB, TF card).

Cons:

- Mixed customer reviews regarding software issues and support challenges.

- Limited working area of 80x80x30 mm may not suit larger projects.

- Some users may find the learning curve for software setup to be steep.

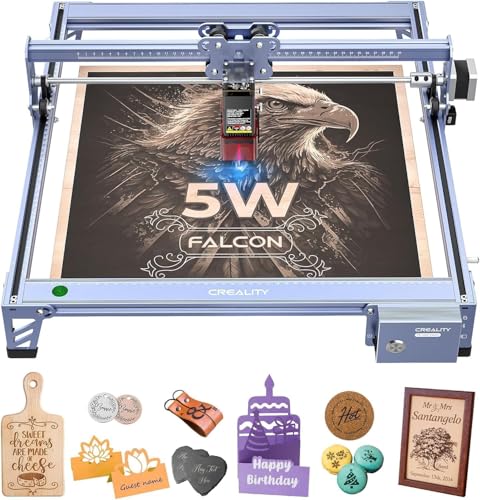

Creality Falcon 5W Laser Engraver Machine

The Creality Falcon 5W Laser Engraver Machine stands out as an excellent choice for jewelry makers seeking precision and efficiency in their engraving tasks. With its 0.06mm ultra-fine laser spot and impressive engraving speed of 10,000 mm/min, you can achieve intricate designs quickly. This machine works with over 200 materials, including wood, leather, and acrylic, making it versatile for various projects. Its safety features, like an eye-protective cover and active stop function, guarantee a secure working environment. While it offers easy assembly, some users report a learning curve with the software. Overall, it’s a solid investment for your jewelry-making needs.

Best For: Jewelry makers looking for a high-precision laser engraver that delivers efficiency and versatility in engraving various materials.

Pros:

- Ultra-fine 0.06mm laser spot allows for intricate and detailed designs.

- Capable of engraving over 200 materials, providing versatility for different projects.

- Safety features like an eye-protective cover and active stop function enhance user security.

Cons:

- Some users experience a learning curve with the setup and operation of the software.

- Mixed reviews on the clarity of assembly instructions may lead to confusion.

- Customer feedback indicates that not all users find the machine easy to operate initially.

Factors to Consider When Choosing a Jewelry Laser Soldering Machine

When you’re choosing a jewelry laser soldering machine, you’ll want to evaluate several key factors. Think about the power and voltage ratings, as well as the compatibility with different welding materials. Additionally, adjustable settings, safety features, and the machine’s size and portability can greatly impact your experience and results.

Power and Voltage Ratings

Choosing the right power and voltage ratings for your jewelry laser soldering machine can greatly impact your welding results. Typically, power ratings range from 100W to 150W, affecting the machine’s performance and welding depth, which can vary from 0.1 to 2.5mm. If you need versatility, look for machines with adjustable power settings, as they can handle different materials like gold, silver, and titanium. Voltage ratings usually come in 110V and 220V options, so make sure your machine matches your region’s electrical systems. A consistent voltage supply is essential to maintain stability and prevent overheating during extended operations. By considering these factors, you’ll enhance your soldering precision and efficiency.

Welding Material Compatibility

Understanding power and voltage ratings sets the stage for evaluating welding material compatibility in jewelry laser soldering machines. You need to verify that the machine you choose works well with the materials you’ll be using—gold, silver, platinum, and various alloys like cobalt chrome and titanium. Pay attention to the welding depth capability, typically ranging from 0.1 to 2.5mm, to match the thickness of your materials for effective soldering. Different welding techniques, such as laser welding and pulsed argon arc welding, can produce varying results, impacting quality and appearance. Also, consider the laser wavelength, commonly around 1064nm, for its effectiveness on different metals. Finally, check if the machine operates with or without argon gas to enhance weld quality.

Adjustable Settings and Features

Selecting the right jewelry laser soldering machine involves paying close attention to adjustable settings and features that can greatly impact your work. Look for machines with adjustable pulse width settings, ideally ranging from 0.1 to 15ms, which allow you to tailor the welding process based on material thickness and type. Consider the laser frequency capabilities, ideally between 0-50Hz, for peak welding speed and efficiency. A spot adjustment range of 0.2 to 2mm guarantees precision when working on small components or intricate designs. Don’t overlook a user-friendly digital control system, as it simplifies parameter adjustments. Finally, an integrated cooling system, like air cooling, is essential to prevent overheating during extended sessions, securing consistent performance.

Safety Mechanisms and Design

When it comes to jewelry laser soldering machines, safety mechanisms and design play a significant role in ensuring both effective operation and user protection. Look for machines with automatic shielding systems that shield your eyes from laser irritation during use. A fully enclosed design is essential to prevent accidental exposure to the laser beam, ensuring compliance with safety standards. Additionally, tilt detection systems can halt operation if the unit tilts too far, minimizing accident risks. Make sure the machine has a cooling system to prevent overheating during extended use, which protects both the operator and the unit. Finally, user-friendly designs with ergonomic features and intuitive controls make safe operation easier, especially if you’re new to laser welding technology.

Size and Portability Factors

The size and portability of a jewelry laser soldering machine can greatly influence your workspace efficiency. Compact models are perfect for small or home-based workshops, helping you stay organized. If you often travel or work at different job sites, consider lighter machines that weigh less than 15 pounds. Their dimensions can vary widely; some are as small as 7.48 x 6.46 x 3.86 inches, making storage and transport easy. While a smaller, portable design might sacrifice some features, it offers ease of use and accessibility for both DIY enthusiasts and professionals. Ultimately, think about whether a stationary or portable option aligns better with your workspace and workflow needs, as this can considerably impact your productivity and convenience.

Warranty and Technical Support

A solid warranty and reliable technical support can make all the difference when choosing a jewelry laser soldering machine. Look for machines that offer at least a one-year warranty, as this shows the manufacturer’s confidence in their product’s durability. Additionally, lifetime technical support can be invaluable for ongoing maintenance and troubleshooting. Some models even provide video instructions for setup and operation, making it easier to learn. Pay attention to customer feedback regarding technical support responsiveness; it can greatly impact your overall satisfaction. Finally, consider return policies like a 30-day guarantee, giving you peace of mind knowing you can return the machine if it doesn’t meet your expectations. Prioritize these factors for a smoother experience.

Cost and Budget Considerations

Understanding warranty and technical support helps you appreciate the importance of budgeting for a jewelry laser soldering machine. Start by setting a clear budget that includes both the initial purchase price and ongoing operational costs. Prices can range from around $100 for basic models to over $1,000 for advanced systems. While it might be tempting to choose a lower-cost option, consider the long-term savings of a higher-quality machine that minimizes repair costs and boosts welding efficiency. Don’t forget to factor in additional expenses like maintenance, replacement parts, and necessary accessories, which can greatly increase your total cost of ownership. Finally, compare different welding technologies, as investing in laser welding might lead to better outcomes despite higher upfront costs.